Giant magnetoresistance (GMR) technology offers key advantages for a range of automotive applications. Learn how it works, how it compares to alternative methods, and the types of GMR sensor solutions available.

Giant magnetoresistance (GMR) elements are a breakthrough in nanotechnology and an important technology in today's automotive system design. These sensors have high sensitivity and precision, which not only improves the accuracy and reliability of various automotive systems, but also improves vehicle safety and efficiency.

In this article, we will explore the operating principles, models and advantages of GMR sensors and introduce some sensor solutions for automotive applications.

GMR Sensor: Basic Working Principle

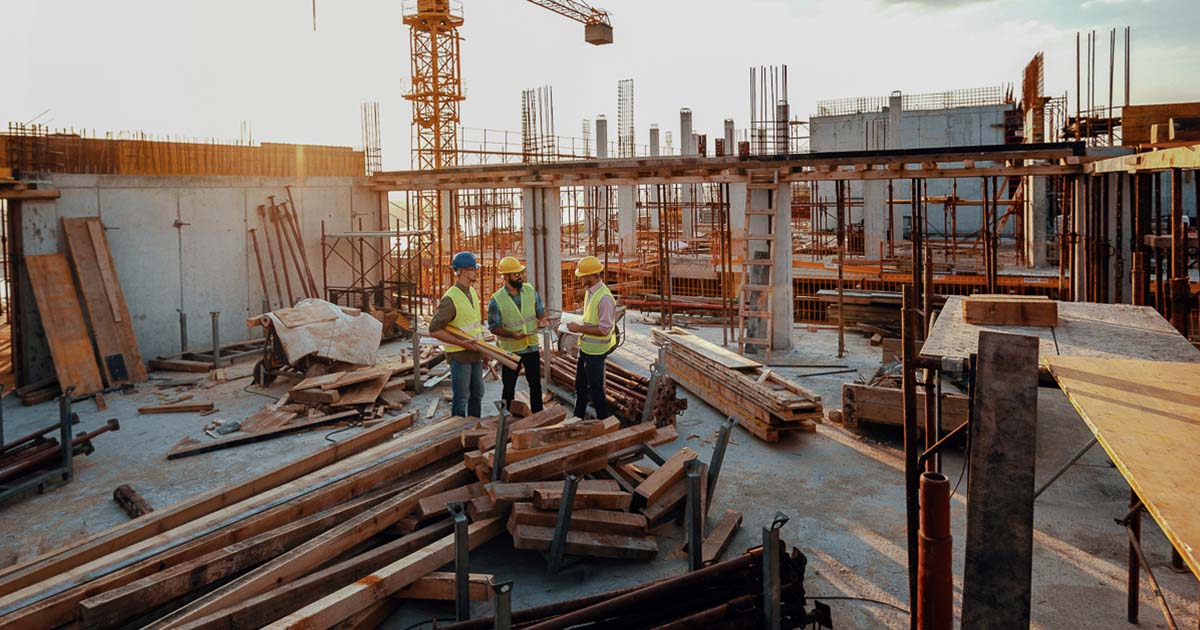

The working principle of GMR sensor is giant magnetoresistance. This is a quantum mechanical phenomenon observed in multilayer thin film structures with alternating ferromagnetic and nonmagnetic layers (Figure 1). Due to the alignment of electron spins in the ferromagnetic layer, the resistance of these structures changes with changes in external magnetic fields.

GMR sensors work by alternating ferromagnetic and non-magnetic layers. The resistance value changes as the external magnetic field changes.

Figure 1. GMR sensors work by alternating ferromagnetic and nonmagnetic layers. The resistance value changes as the external magnetic field changes.

This arrangement can be parallel or antiparallel, which affects electron scattering and changes resistance. In a parallel arrangement, scattering is reduced, resulting in lower resistance, whereas an anti-parallel arrangement increases scattering and resistance. The ability of these sensors to detect changes in magnetic fields results from this variable resistance characteristic, allowing them to serve as highly accurate and reliable sensor elements.

The evolution of automotive sensing technology

Traditionally, cars have relied on mechanical or less sensitive electromagnetic sensors to enable various functions within the vehicle. While fully functional, these older systems have limitations in accuracy, durability, and efficiency:

Speed and position sensing: In the past, vehicles have mostly used mechanical systems or basic magnetic sensors to determine speed and position. Not only are these systems prone to wear and tear, but they also have accuracy issues.

Engine Timing: Early engine timing mechanisms were primarily mechanical and often lacked the precision required by modern engines, resulting in incomplete fuel combustion and higher emissions. The mechanical characteristics of these systems also make them more susceptible to degradation over time, compromising the overall efficiency and reliability of the engine.

Safety Systems: Initial versions of critical safety systems, such as anti-lock braking systems (ABS), faced efficiency challenges. This is primarily due to the limited accuracy of the sensors that detect wheel speed and slip. Therefore, early ABS systems cannot effectively prevent wheel locking during emergency braking, which may endanger vehicle safety.

Saturated model and linear model

In the saturation model, the GMR sensor operates with a magnetic field strong enough to align all magnetic moments within the ferromagnetic layer, resulting in a maximum reduction in resistance. However, after reaching saturation, the sensor's sensitivity to further increases in magnetic field strength decreases significantly.

Key characteristics of saturated models include:

Strong magnetic field: A strong magnetic field is necessary to achieve saturation.

Binary Output: Ideal for applications requiring a simple on/off response.

Stability: less sensitive to small fluctuations in the magnetic field when saturated.

The linear model operates in the lower magnetic field range, where the alignment of the magnetic moments is incomplete. This partial alignment provides a relationship between magnetic field strength and resistance that is generally linear, although there may be deviations based on material properties and sensor design.

Characteristics of linear models include:

High Sensitivity: Highly responsive to small changes in magnetic fields.

Proportional response: Provides a continuous, quasi-linear response to changes in magnetic field strength.

Dynamic Range: Suitable for applications requiring sensing of a range of magnetic field strengths.

The choice between saturated and linear models depends on the specific application within the vehicle. Linear models are generally more complex and are used in systems where detailed information is required. In automotive applications, they are suitable for precise measurement of component position, providing response gradients that allow fine-tuning of engine timing.

Saturated models are used when there is sufficient binary information, such as detecting the presence or absence of a component at a specific location. In terms of cost and integration, the saturated model is simpler, cost-effective, and easier to integrate into various parts of the vehicle as well as in space-constrained automotive applications.

Things to consider when selecting components

The choice between saturated and linear models depends on the specific application within the vehicle. Linear models used for wheel speed detection in systems such as ABS are typically more complex and suitable for precise measurement of component position or orientation. They provide gradient response, allowing for fine-tuning in applications such as engine timing.

The saturation model is well suited for applications where binary information is sufficient, such as a simple proximity sensor used to detect the presence of a component at a specific location. Their designs are simpler in terms of cost and integration, making them cost-effective, robust, and easier to integrate into various parts of the vehicle, including space-constrained applications.

Benefits in Automotive Applications

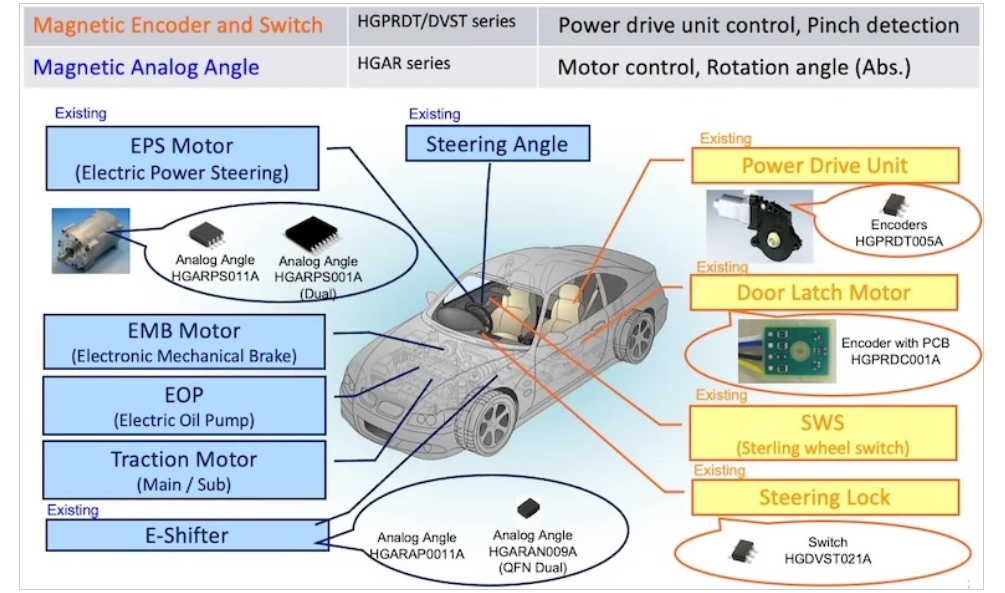

The ability to detect small changes in magnetic fields has enabled the development of high-precision speed and position sensors based on GMR technology. GMR sensors accurately measure the position of the crankshaft and camshaft, which is critical to engine timing. This also helps optimize fuel injection and ignition timing, resulting in more efficient fuel utilization and reduced emissions (Figure 2).

Various automotive subsystems can take advantage of GMR.

Figure 2: Various automotive subsystems can leverage GMR.

Integrating GMR sensors into safety systems such as ABS and electronic stability control (ESC) can also increase their effectiveness. These sensors detect wheel speed and slip more quickly and accurately, providing a more responsive and reliable safety system.

As the global automotive industry shifts toward electric vehicles (EVs) to minimize emissions, GMR technology will play a potential role in battery management systems. Accurate sensing of current and voltage is critical to optimizing battery performance and life.

Likewise, GMR sensors will become an integral part of the development of autonomous vehicles due to their high sensitivity and accuracy, which are critical to the complex sensing requirements of autonomous vehicles.

Sensor solutions for automotive applications

For its part, Alpine offers a wide range of sensors based on GMR technology suitable for automotive applications. Its GMR-based sensors include angle sensors, encoders and switches, providing a range of performance- and safety-enhancing features.

Key advantages include:

High stability: Ensure stable performance of key automotive systems.

Low Noise: Minimizes electromagnetic interference, ensuring highly accurate and reliable readings.

Low power consumption: suitable for automotive applications where energy efficiency is a priority.

High Sensitivity: Able to detect small angle changes for precise control.

High Durability: Durable and able to withstand harsh automotive environments.

Wide operating temperature range: Suitable for a variety of typical climate conditions found in automotive environments.

Now let’s look at some GMR based sensor solutions.

HGARPS011A and HGARAN angle sensors

The HGARPS011A angle sensor is available in a TSSOP-8 package, making it ideal for space-constrained applications (Figure 3). The product offers the versatility of two directions and two full bridges, increasing sensor accuracy. Additionally, the wide operating temperature range (-40°C to +150°C) ensures reliability in high-temperature environments typical of automotive settings. Key applications include steering angle, gear shifting and motor control systems such as EPS.

The HGARPS011A, available in a TSSOP-8 package, is an angle sensor ideal for space-constrained automotive applications.

Figure 3. The HGARPS011A, available in a TSSOP-8 package, is an angle sensor ideal for space-constrained automotive applications.

The HGARAN series features bi-phase outputs and two full bridges to provide detailed corner detection. Its small DFN1810 package enables seamless integration into compact systems. Designers can take advantage of HGARAN to reduce power consumption due to the low current consumption and 5kΩ bridge resistance. Primary applications include position detection and motor control.

HGPRDT007A and HGDVST encoders

The HGPRDT series encoder (HGPRDT007A) comes in a compact SOT-23 package with two-phase output, enabling high-precision rotation and motor control systems. This product family features high output stability, ensuring consistent performance under different operating conditions. Key applications include power windows, sliding doors, tailgates and sunroofs (Figure 4).

Compared to traditional Hall encoders, the HGPRDT007A GMR encoder provides two-phase outputs with a 50% phase shift in one package.

Figure 4. Compared to traditional Hall encoders, the HGPRDT007A GMR encoder provides two-phase outputs with a 50% phase shift in one package.

The HGDVST is designed as a unipolar, single output switching output sensor in a small SOT-23-5 package. This product has a high degree of resistance to electromagnetic interference, which is a basic quality in the complex electromagnetic environment of today's automobiles.

The device is suitable for contactless automotive applications such as door lock and tailgate position detection. Compared with mechanical switches, its non-contact nature ensures a longer service life and is less prone to wear and tear.

More efficient vehicle design technology

GMR components are not only changing existing automotive technology but also paving the way for future innovations. The accuracy, sensitivity and reliability of GMR technology continue to drive improvements in vehicle performance, safety and efficiency. As technology advances, the potential use of GMR components in automotive applications will expand, helping to develop more efficient automotive designs.